Cylinder deactivation

Cylinder deactivation refers to a system which reduces the fuel consumption of internal combustion engines. Its function involves some of the cylinders in the engine being temporarily stopped.

Function

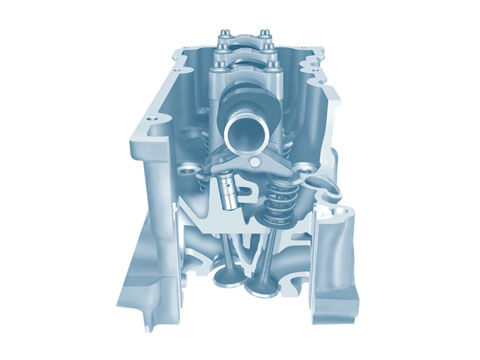

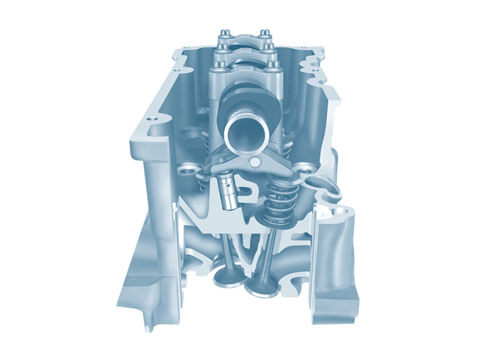

In nearly all petrol engines, cylinder deactivation systems enable cylinders which are not required to be shut off in partial-load operation. When the driving situation permits cylinders to be deactivated, such as when there is a moderate engine torque requirement on rural roads, the engine shuts off some of the cylinders. This deactivation means that the cylinders which remain active must continue to generate the torque of the cylinders which have been deactivated. For the cylinders still in operation, this results in a higher load point which is thus optimised for efficiency: an engine has a specific degree of efficiency at every load point. The optimum degree of efficiency is in the medium rpm range, although this depends on the engine design, control system and so forth. The requirements for cylinder deactivation are as follows:

- Torque neutrality

- Emissions neutrality

- Good responsiveness

Protection of the environment

The shift in load point and partial omission of the gas exchange (i.e. the exchange of combusted exhaust gas for fresh gas in the cylinder’s chamber) reduces fuel consumption and also CO2 emissions.