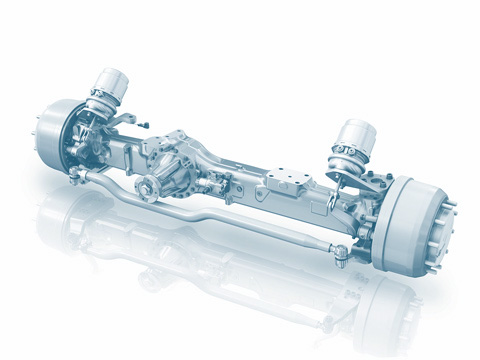

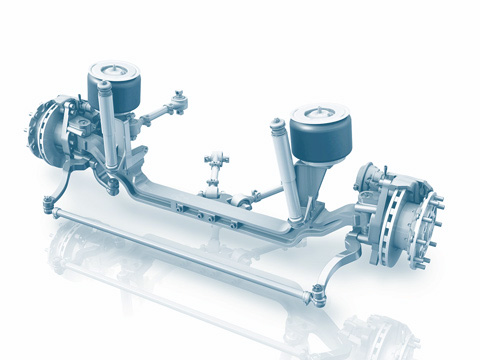

Stabiliser

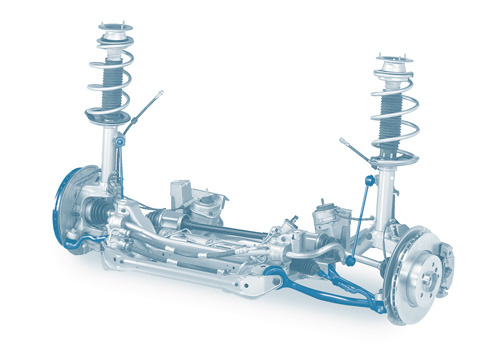

The stabiliser is a component of the chassis; it operates as a suspension component when cornering to reduce rolling of the vehicle.

Function

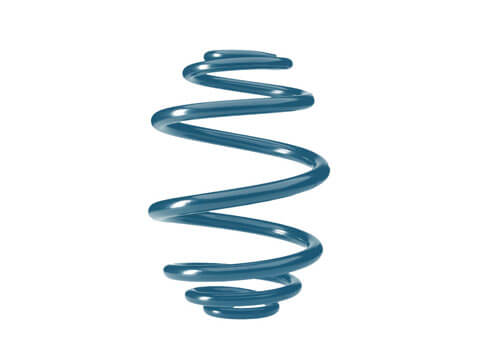

Whilst spring/damper systems are mainly responsible for the up and down conditions of a wheel, additional stabilisers are sometimes used for roll reduction. The stabiliser is connected to the wheel suspension via the connecting rods. The stabiliser therefore links both wheels to each other. A rolling movement occurs when a wheel compresses on one axle, whilst the other decompresses. In such a case, the stabiliser turns (“is twisted”). There is a return torque around the rolling axis. This not only reduces the rolling angle, but also influences the dynamic wheel load differences on an axle when cornering; these also have an effect in turn on the traction and tracking of a vehicle. This means the stabiliser improves the road position and driving characteristics.

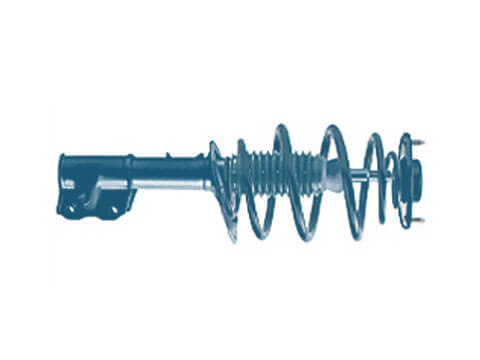

Safety

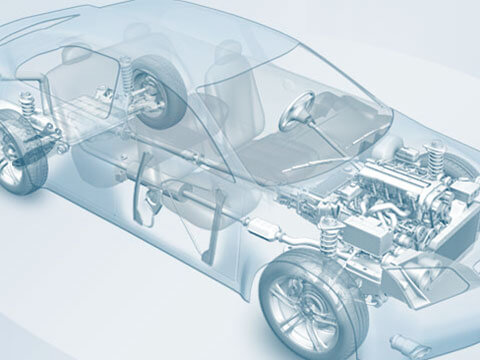

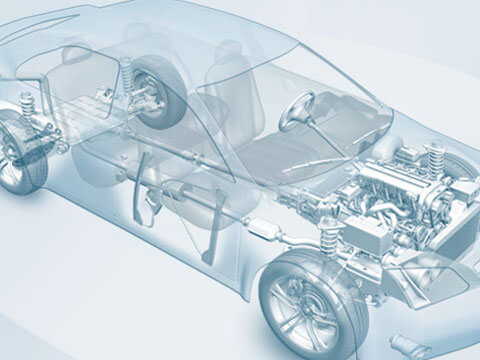

Together with the other wheel suspension components, the stabiliser is crucial for stable handling, and therefore also for the safety of the passengers. A malfunction or the failure of one of the wheel suspension components can have major consequences for the road safety of a vehicle – even endangering life and limb. To prevent dangers from developing, it is important to ensure that only trained personnel work on the chassis. They should regularly inspect and test all components.

Value retention

State-of-the art technologies are used in modern vehicles. These guarantee a long service life for the wheel suspension components, which is also positively reflected in the breakdown statistics. In turn, this helps to stop a vehicle’s value depreciating.