Recuperation and regenerative brake systems

In electric vehicles, regenerative brake systems use the principle of energy recuperation. When the vehicle is braked, kinetic energy is converted into electric energy which is stored temporarily in the battery and can be used later on to power the vehicle.

Function

When vehicles with an internal combustion engine are braked, motion energy, also known as kinetic energy, is converted into heat. As a result, when the driver brakes the vehicle using the wheel brakes or takes their foot off the accelerator, this energy is lost due to the engine braking torque. In contrast, on electric vehicles and hybrid vehicles some of the kinetic energy can be recovered and reused. This is known as “recuperation”. The term comes from the Latin word “recuperare”, which means to recover or regain.

During recuperation, the electric motor in the hybrid or electric vehicle switches over to generator mode when the vehicle is braked. The wheels then transmit the kinetic energy via the driveline to the generator. The generator turns (like the dynamo on a bike) and converts some of the kinetic energy to electric energy, which is then stored temporarily in the battery and can be used later on to power the vehicle. The recuperation process thus helps to extend the vehicle’s range.

The recuperation process also generates a braking torque that decelerates the vehicle. The braking power provided by the generator is often sufficient to adequately brake the vehicle if required. If more braking power is needed, the vehicle is additionally braked using the conventional brake. With regenerative braking, the friction brake is used much less often overall. This means that the wear on brake discs and pads/linings is much lower than on conventional vehicles without such a recuperation function. However, because the disc brakes are used less often, they are more susceptible to corrosion (flash rust) and may lose their braking force if they are not used for a long time.

Protection of the environment

Electric motors do not emit any emissions at a local level, which makes them more environmentally friendly than internal combustion engines. However, the production of the electrical power itself may produce harmful substances. The most environmentally friendly solution is when 100% renewable energy sources are used to generate power.

Recuperation, together with the high efficiency of electric motors, helps to reduce the energy consumption of electric vehicles relative to vehicles powered by a conventional internal combustion engine.

Brake dust is generated when the friction brake is used. As a result of the recuperation process, regenerative brake systems in electric vehicles can also reduce brake particle emissions, in some cases significantly.

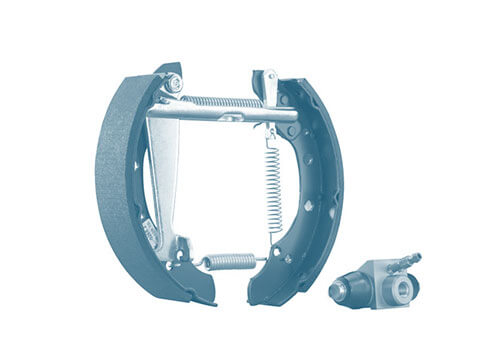

Drum brakes offer a major advantage in this respect as their enclosed design means the brake dust accumulates inside the drum brake, resulting in barely any particle emissions.

Safety

The recuperation process causes temporary peak loads and high electric currents, which lead to the battery cells heating up sharply. That is why it is all the more important to provide a powerful thermal management system to adequately cool the cells.