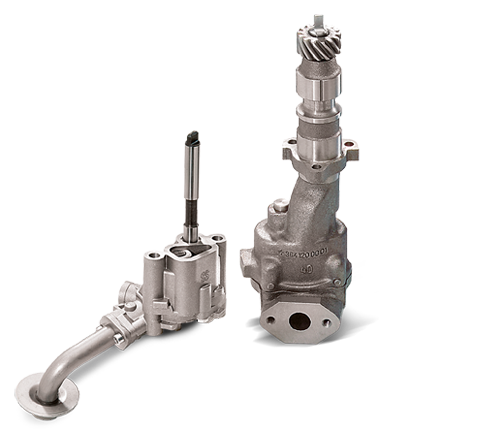

Oil pump

The oil pump is responsible for conveying the oil for engine lubrication and building up the oil pressure in the lubrication system.

Function

Oil pumps are usually operated by the crankshaft by way of auxiliary drives. The delivery of the oil pump is governed by its size, speed and design.

There are several important reasons for engine lubrication:

- To supply all sliding components with sufficient oil to reduce friction and wear

- Cooling of engine components to prevent overheating

- Corrosion protection

- Damping of noise and vibration

- Fine sealing between piston and cylinder wall, with the piston rings being mainly responsible for the sealing action

Oil pump systems

The following different oil pump systems are available:

Gear pumps

Gear pumps are usually of the push-on type or designed as pumps with gear or chain drive. Their speed can be selected by way of the transmission ratio. The delivery depends on the speed and the tooth gaps of the gear wheels. Gear pumps are relatively inexpensive to manufacture.

Crescent-type pumps

Crescent-type pumps are located in a space-saving position on the control end of the crankshaft. They are driven directly by the crankshaft and their speed is thus the same as that of the crankshaft. As compared to a gear pump, a crescent-type pump can provide a higher maximum oil pressure and a high delivery rate even at low speeds.

Rotor-type pumps

Like crescent-type pumps, rotor-type pumps are located on the control end of the crankshaft and driven directly by this. They attain high oil pressures and delivery rates and are also very quiet-running.