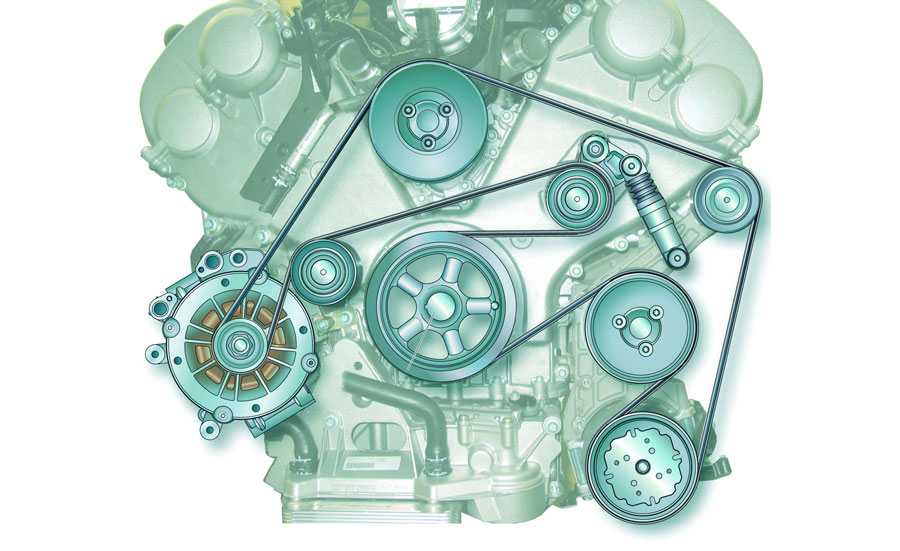

Belt drive components

Belt drives can be found in every modern engine. They must transmit the rotation of the crankshaft to and drive the engine control or ancillary components. The use of toothed belts to drive camshafts...

Function

Belt drives can be found in every modern engine. They must transmit the rotation of the crankshaft to and drive the engine control or ancillary components.

The use of toothed belts to drive camshafts is widespread in modern engines. They are lighter and quieter than timing chains. The components of a toothed belt drive are the toothed belt itself, a belt tensioner, tensioning pulleys and deflection rollers as well as the toothed wheels at the crankshaft, the camshaft and the ancillary components. Toothed belts are made from synthetic rubber compounds and embedded glass tension cords. Force is transmitted via the teeth without slip. Over time, a variety of tooth designs have established themselves.

Alongside toothed belts, V-belts and V-ribbed belts are used in modern engines to drive ancillary components such as fans, alternators, compressors or hydraulic pumps. V-ribbed belts are exposed to high levels of stress and strain by the torques to be transmitted, dynamic loads and changing temperatures.

Belt drive components in all vehicles are expected to meet maximum performance requirements. Ancillary components will only function perfectly if belt drive components are achieving optimum levels of performance.

The use of toothed belts to drive camshafts is widespread in modern engines. They are lighter and quieter than timing chains. The components of a toothed belt drive are the toothed belt itself, a belt tensioner, tensioning pulleys and deflection rollers as well as the toothed wheels at the crankshaft, the camshaft and the ancillary components. Toothed belts are made from synthetic rubber compounds and embedded glass tension cords. Force is transmitted via the teeth without slip. Over time, a variety of tooth designs have established themselves.

Alongside toothed belts, V-belts and V-ribbed belts are used in modern engines to drive ancillary components such as fans, alternators, compressors or hydraulic pumps. V-ribbed belts are exposed to high levels of stress and strain by the torques to be transmitted, dynamic loads and changing temperatures.

Belt drive components in all vehicles are expected to meet maximum performance requirements. Ancillary components will only function perfectly if belt drive components are achieving optimum levels of performance.

Safety

To avoid damage, correct belt tensioning must be ensured at all times. A belt that is too slack will cause the belt to slip and oscillate, resulting in premature wear of the belt components. In the timing drive and the ancillary drive, the consequences of a slack belt are even more serious, ranging from changes to timings to the engine being written off. Therefore, tolerances due to heat expansion and age-induced wear must be equalised.

To safeguard operational reliability and long service life, the individual components of the belt drive must meet hugely challenging requirements not only where quality and accuracy of fit are concerned but also in relation to correct installation. Only if all components are in perfect harmony will smooth running be achieved.

To avoid damage, correct belt tensioning must be ensured at all times. A belt that is too slack will cause the belt to slip and oscillate, resulting in premature wear of the belt components. In the timing drive and the ancillary drive, the consequences of a slack belt are even more serious, ranging from changes to timings to the engine being written off. Therefore, tolerances due to heat expansion and age-induced wear must be equalised.

To safeguard operational reliability and long service life, the individual components of the belt drive must meet hugely challenging requirements not only where quality and accuracy of fit are concerned but also in relation to correct installation. Only if all components are in perfect harmony will smooth running be achieved.

Depreciation

First-class products are one of the prerequisites for belt drives to be in perfect working order. Due care and attention, along with compliance with the installation requirements set out by the manufacturer also play an important role. Setting the belt tension incorrectly, using the wrong tools or impurities due to oil and fuels are just some examples of the possible causes that can result in belt drive components having significantly reduced service lives and sustaining damage.

Environmental protection

A belt drive is lighter in weight than a chain drive. This results in a reduction in moving masses. As consequence, fuel consumption and thus CO2 emissions are lower.