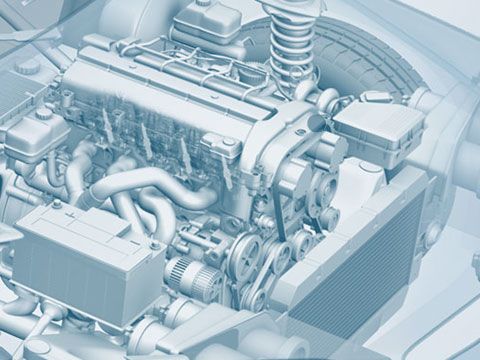

Engine mounts

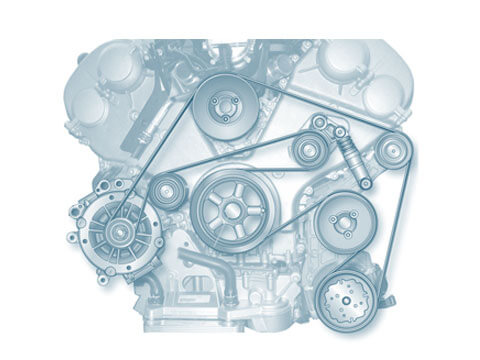

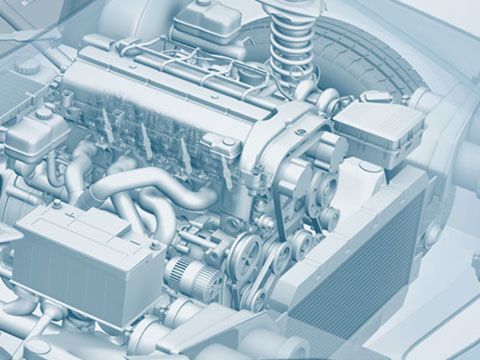

In vehicles, the engine mounts create the connection between the engine and the body.

Function

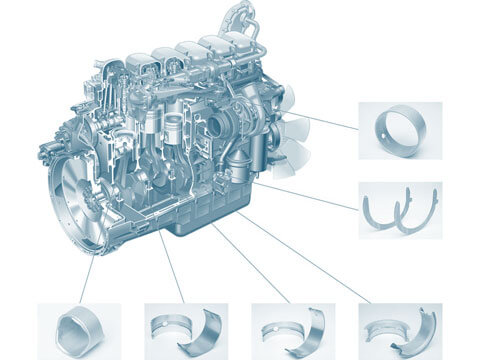

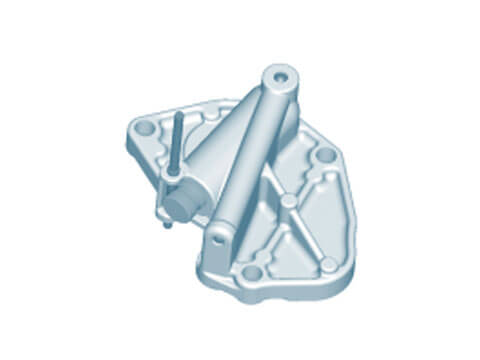

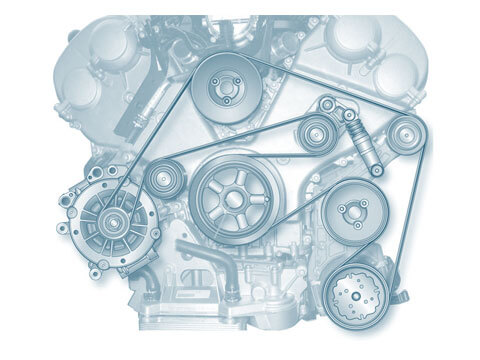

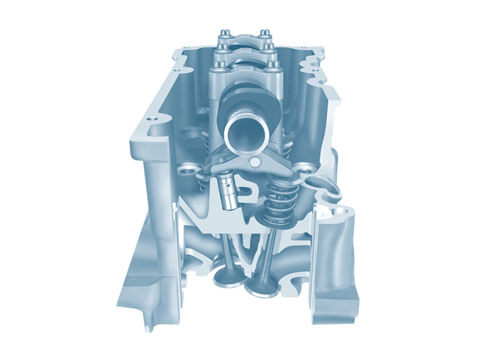

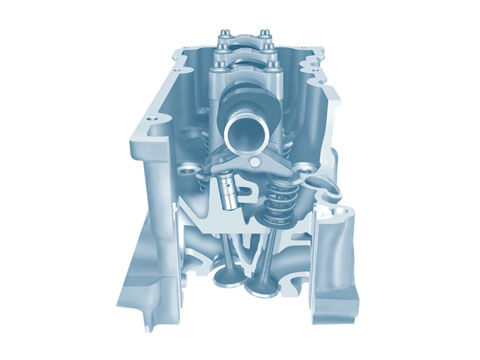

Classic engine mounts consist of a sophisticated combination of metal and elastomer. They create the connection between the engine/transmission package and the vehicle body and limit the movement of the drive due to the engine load, but also due to driving influences. Vibration and structure-borne noise from the drive is also prevented from being transmitted to the body. An engine mount can only compensate for vibration and ensure driving comfort when the technical set-up and the rubber/metal connection have been coordinated for the respective vehicle and engine characteristics.

Hydraulic engine mounts

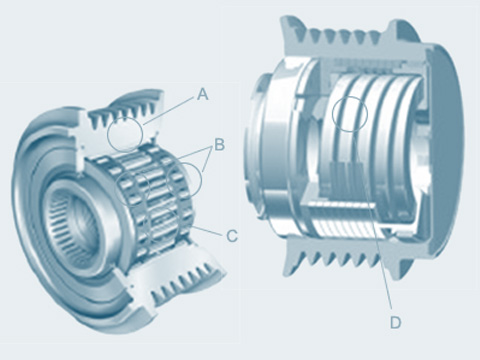

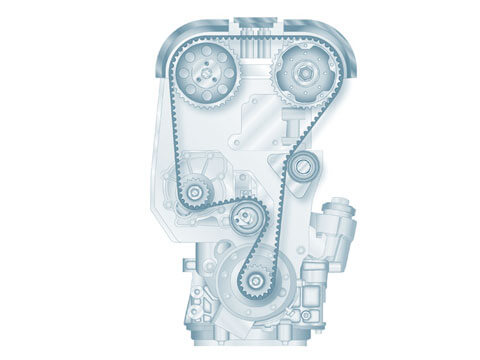

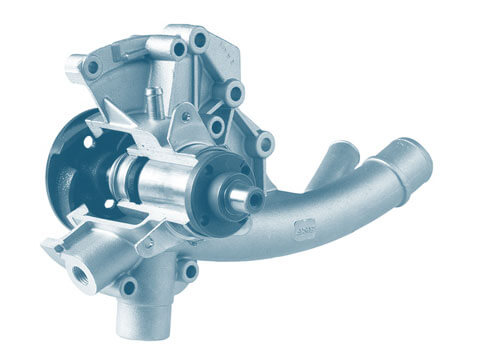

Hydraulic engine mounts combine the high isolation performance of a conventional rubber engine mount with a higher damping performance. In a similar manner to the damping in a shock absorber, the oil within the rubber element is pressed from one chamber into another chamber in the event of dynamic excitation. In this way, the fluid provides flow resistance, which lessens shocks and vibration. The damping depends on the design (such as the cross-section) of the channel system which connects both chambers.

Electronically switchable engine mounts

The requirements placed on engine mounts are becoming ever more demanding. Modern engines are becoming more compact, often have fewer cylinders and less capacity, increasingly frequently have turbocharging, direct injection and new technologies such as cylinder deactivation. They are designed with the aim of saving fuel, having state-of-the-art driving dynamics and providing the highest level of comfort in the passenger compartment. Electronically switchable engine mounts increase the options provided by conventional, hydraulic engine mounts. They can be actively controlled and can adapt to different situations. Depending on the engine excitation frequency, the engine mount dampens on a purely hydraulic, passive or active basis. The isolation characteristic is calculated by the control unit and implemented by the actuator so that there are no critical vibrations on the vehicle body.

Safety

Engine mounts must ensure a permanent connection between the engine and body. Original components guarantee faultless function. Faulty engine mounts can cause vibration and negatively influence the handling of the vehicle. This is why faulty engine mounts should be replaced immediately.

Value retention

Faulty engine mounts often cause vibration or noises. In this case, an automotive workshop should be contacted immediately. If the engine mounts are faulty, unwanted vibration can be transferred to other components and cause damage there – and the repair of these can lead to high costs. In the worst case scenario, the mount can break and the engine block can move around uncontrolled in the engine compartment. This is why faulty engine mounts should be replaced as quickly as possible.