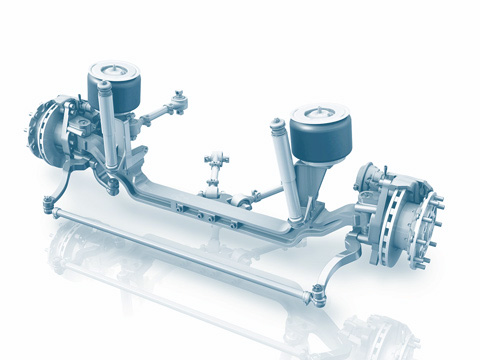

Torsion-beam rear axle

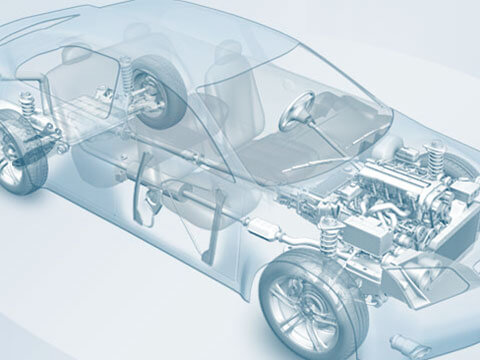

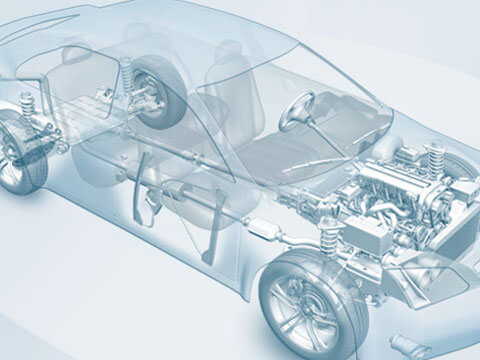

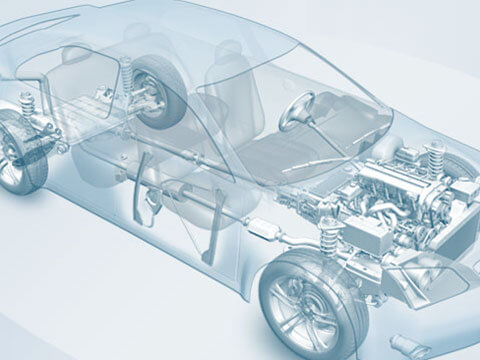

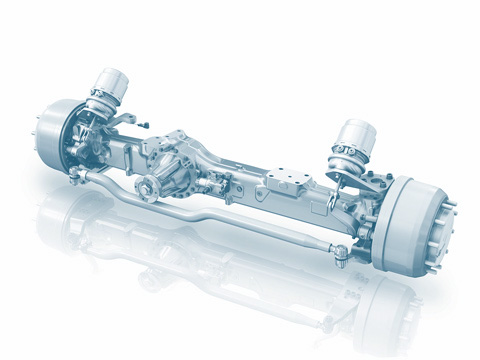

As load-bearing connections between the wheels and body, the axles assume a key function in the chassis system. The axles transfer all forces and torques between the wheels and vehicle bodywork. There is a differentiation between independent suspensions, rigid axles and torsion-beam axles. In the broadest sense, torsion-beam rear axles are a variant of the rigid axle.

Function

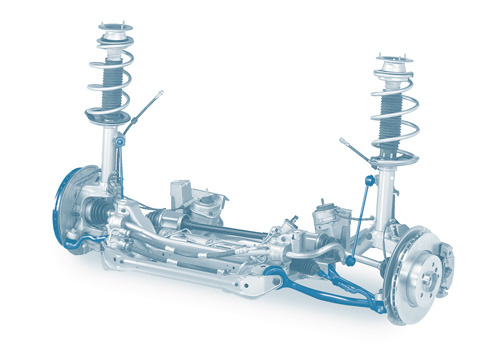

Torsion-beam rear axles are exclusively used as a rear axle for vehicles with front-wheel drive. They are mainly to be found in small vehicles or cars in the compact segment and they establish the connection between the wheels and body. The torsion-beam rear axle must reliably transfer all forces and torques between the wheels and bodywork. Torsion-beam rear axles primarily consist of two bend-proof, torsionally stiff trailing arms and one transverse profile which connects the two trailing arms with low torsional stiffness.

Safety

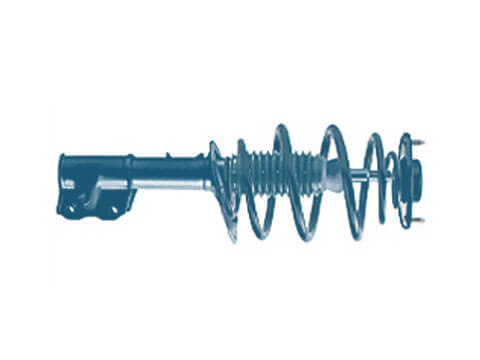

The wheel suspension is instrumental in ensuring safe driving characteristics and thus for passenger safety. A malfunction or failure in one of the components of the wheel suspension can have severe consequences for the road safety of the vehicle concerned. To prevent dangers from developing, it is important to ensure that only trained personnel work on the chassis. They should regularly inspect and test all components. The use of products from well-known OE suppliers is mandatory.

Protection of the environment

The use of permanently lubricated joints conserves resources and stops pollution of the environment caused by excess lubrication.

Value retention

State-of-the art technologies are used in modern vehicles. These guarantee a long service life. In turn, this helps to stop a vehicle’s value depreciating.