Gearbox

Gearboxes convert the torque from an engine into the traction required to drive the vehicle. In electric and hybrid vehicles, gearboxes take the form of electric axle drive systems.

Function

Gearboxes convert the engine torque into the wheel traction required to drive the vehicle. As internal combustion engines only operate in a narrow speed range, gearboxes transform this into the wheel speeds needed to produce the various driving speeds. They do this by providing various transmission ratios to adapt the engine speed to different driving situations.

Unlike internal combustion engines, electric motors cover a wide range of speeds and torques. These electric machines set themselves apart by the fact that the maximum torque can already be provided at low speeds. What’s more, the speed of an electric motor can reach 15,000 rpm, and can even exceed 20,000 rpm depending on the design. Thanks to this wide range of speeds, e-axle gearboxes can be designed with only one gear.

As a basic principle, gearboxes for electric drives are designed according to the same criteria as gearboxes for internal combustion engines – in both cases the driving resistance is a crucial factor in the gearbox design (for determining the gearbox ratio). This usually involves a trade-off between a high moving-off torque and a high final vehicle speed – a high moving-off torque requires a high gearbox ratio, whereas a high final vehicle speed requires a low gearbox ratio.

This conflict can be resolved by using multi-speed gearboxes offering different ratios and by apportioning the available overall power in a sensible way. This can be done either using an additional e-machine or by installing two drives each on the front and rear axle.

Gearboxes in different e-drive concepts

E-axles:

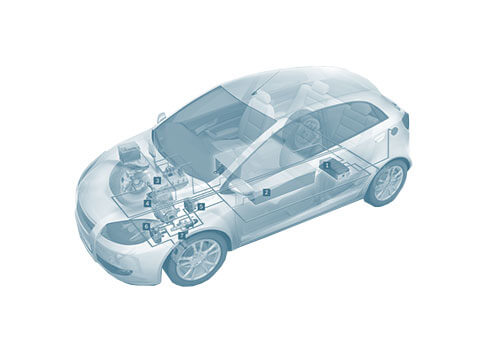

Electric axle drive systems (also known as e-axles) generally combine an electric motor with a gear transmission and a differential gear. They are differentiated into coaxial and parallel axis systems.

Coaxial e-drive axles:

On coaxial e-axles, the e-motor is located on one axis to the side shafts of the wheels.

Parallel axis e-drive axles:

On parallel axis e-axles, the e-motor is located parallel to the side shafts of the wheels.

Wheel hub drive:

With wheel hub drives, the motor speed is practically the same as the wheel speed, and the motor torque is practically the same as the wheel torque. However, depending on the version, a gearbox may also be integrated in the wheel hub module.